Highest hygiene standards

Excellent electropolishing

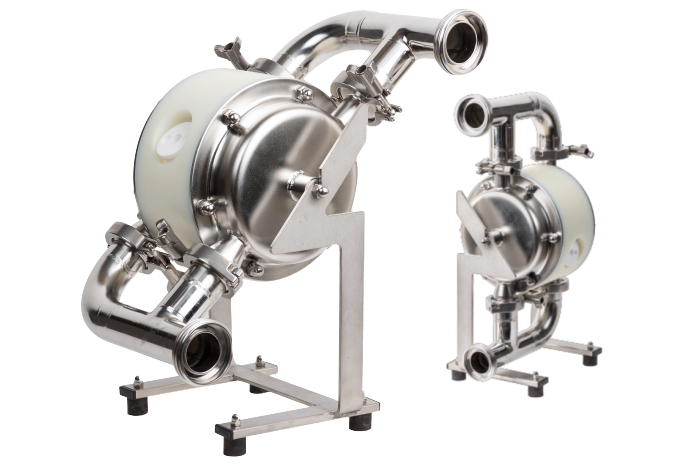

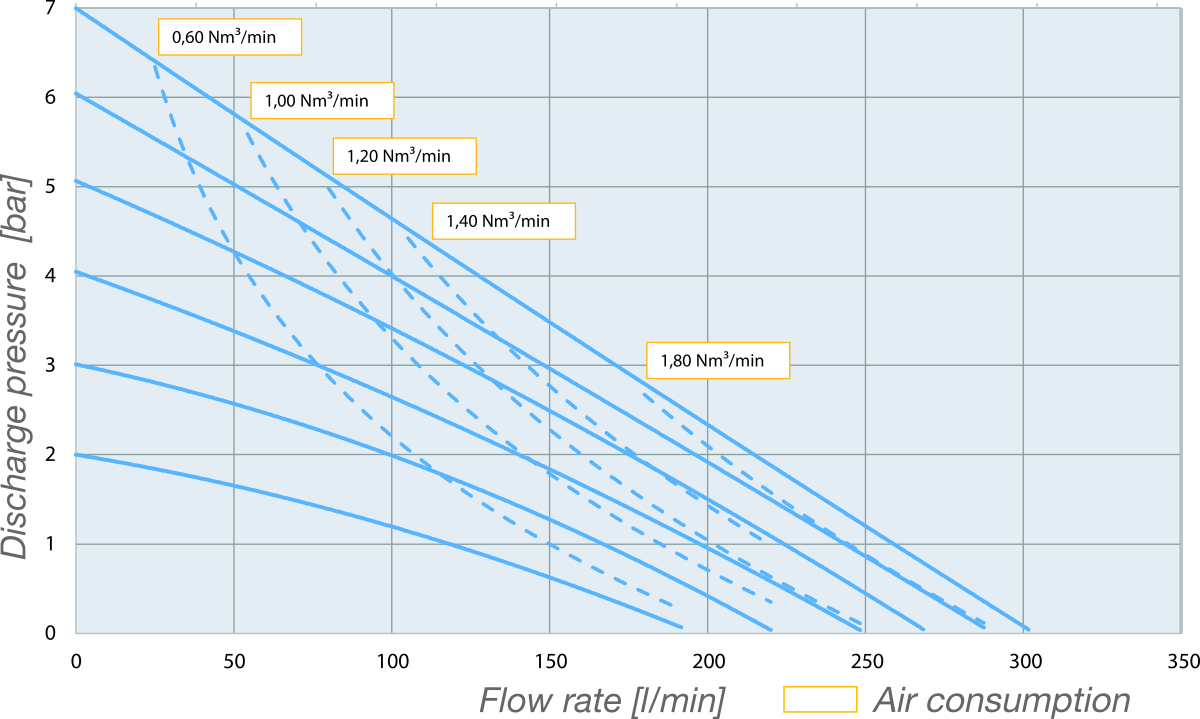

The Verderair HC-PURE series of hygienic two-membrane pumps is designed for various processes in the food, pharmaceutical and cosmetic industries. The highest hygiene principles are observed in the design process. HC-PURE pumps meet the requirements of EC01935 / 2004 and the FDA. The pumps are made of 316L stainless steel in accordance with the highest hygiene standards.

The central unit is made from a single piece of UHMW polyethylene or PA polyamide and is available in ATEX standard. Electropolishing reduces the average roughness, which makes it harder for products to stick and reduces the risk of bacteria getting trapped and contaminated, and the surface becomes more resistant to corrosion. The housing screws and manifold clamps can be easily removed for complete disassembly and cleaning. The molded EPDM/PTFE membranes have a long service life, and the maintenance-free, 100% self-lubricating air valve reduces maintenance and downtime.

The Verderair HC-PURE dual-diaphragm hygiene pump is available in two versions: FD series for hygienic applications at the beginning of the production process and SB series for hygienic applications at the final stage of the production process.

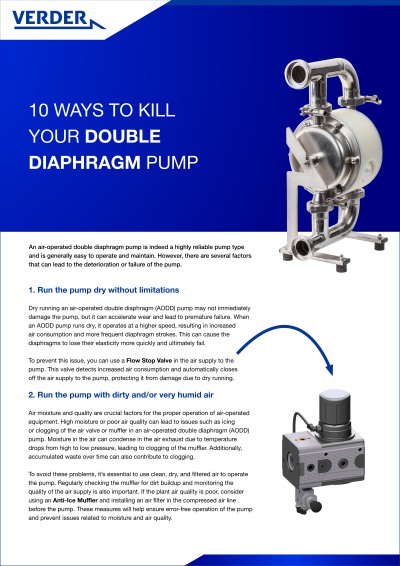

The pneumatic double-membrane pump is really highly reliable and, as a rule, easy to operate and maintain. However, there are a number of factors that can cause the pump to wear out or fail. When the pump is idle, damage may not occur immediately, but this will accelerate wear and lead to premature failure.

When the AODD pump is idling, it runs at a higher speed, which leads to increased air flow and more frequent diaphragm strokes, which lose elasticity faster and eventually need to be replaced.

To prevent this problem, use the Flow Stop Valve. This valve detects increased air flow and automatically cuts off the air supply, protecting the pump from damage due to idling.

The Verderair HC-PURE series of hygienic two-membrane pumps is designed for various processes in the food, pharmaceutical and cosmetic industries. The highest hygiene principles are observed in the design process. HC-PURE pumps meet the requirements of EC01935 / 2004 and the FDA. The pumps are made of 316L stainless steel in accordance with the highest hygiene standards.

The central unit is made from a single piece of UHMW polyethylene or PA polyamide and is available in ATEX standard. Electropolishing reduces the average roughness, which makes it harder for products to stick and reduces the risk of bacteria getting trapped and contaminated, and the surface becomes more resistant to corrosion. The housing screws and manifold clamps can be easily removed for complete disassembly and cleaning. The molded EPDM/PTFE membranes have a long service life, and the maintenance-free, 100% self-lubricating air valve reduces maintenance and downtime.

The Verderair HC-PURE dual-diaphragm hygiene pump is available in two versions: FD series for hygienic applications at the beginning of the production process and SB series for hygienic applications at the final stage of the production process.

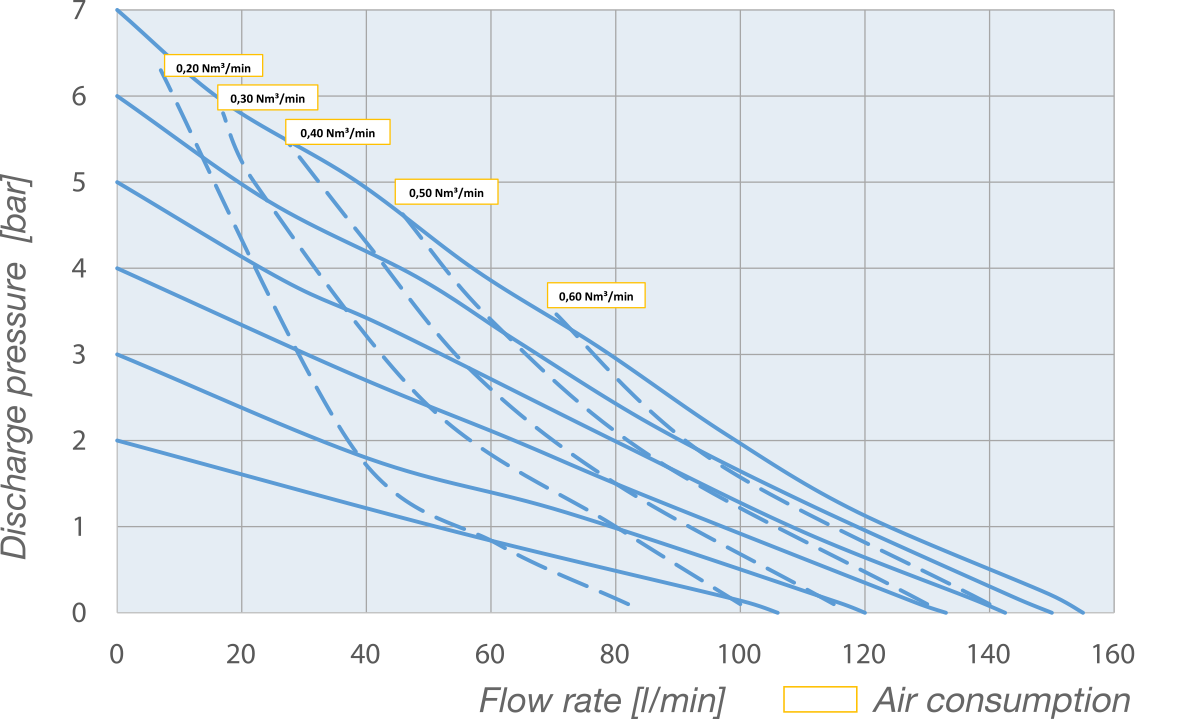

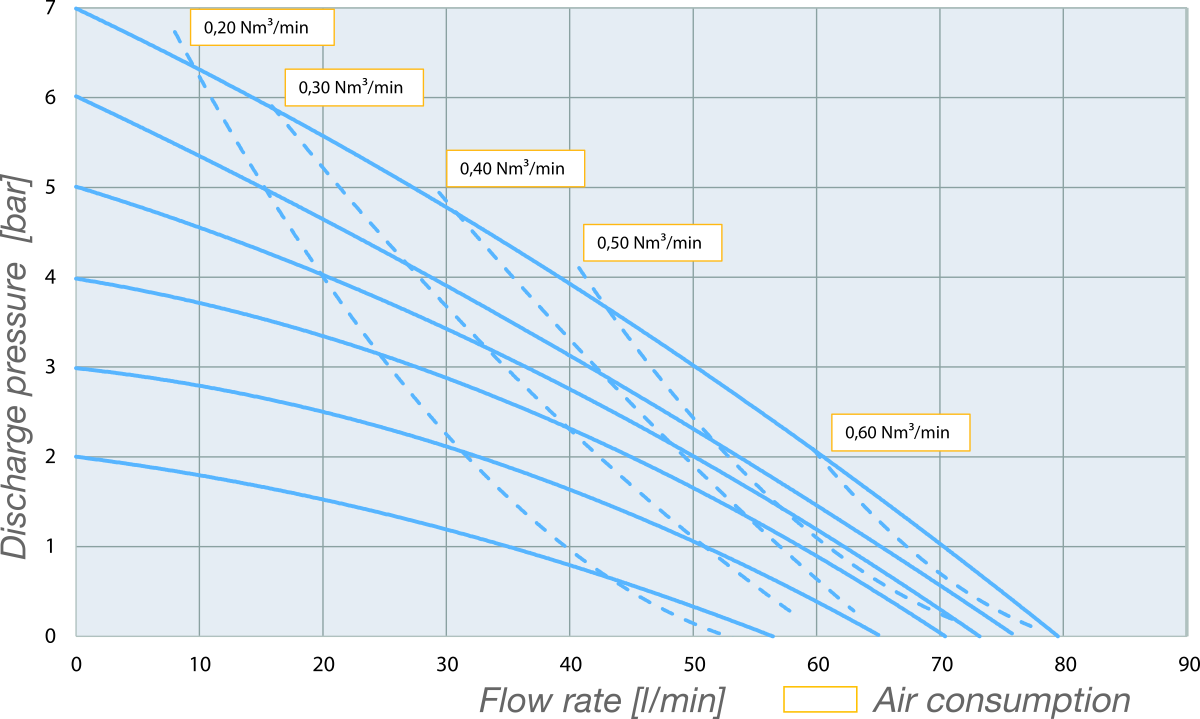

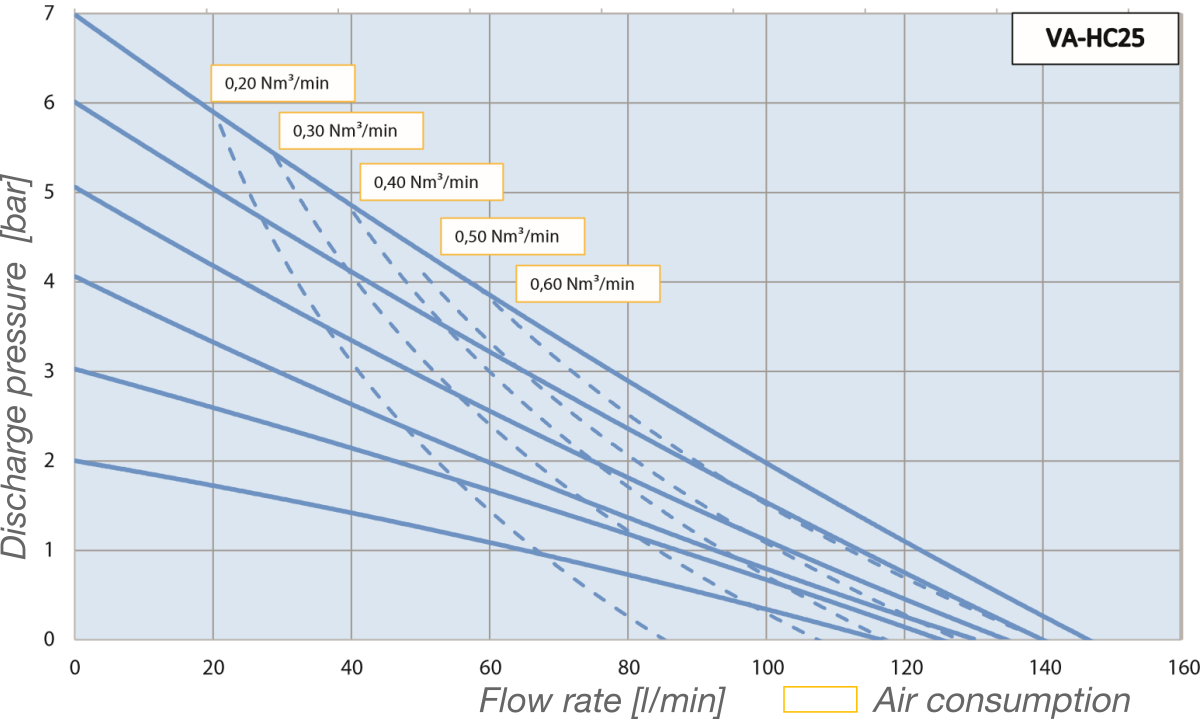

AIR CONTROL PRO-a set of accessories that help regulate the air supply in pumps and protect against premature failure of the air valve and membranes. The Filter-Regulator with semi-automatic drain keeps the pressure of compressed air supplied to the pump at a constant preset level. The Throttle Valve is used in conjunction with a pressure regulator, and the pump can be adjusted even at low flow rates by using the compressed air volume. The Soft Start Valve ensures a slow start of the pump and increases the service life of the membranes. ON-OFF Valve with manual or electric drive. The Flow Stop Valve automatically cuts off the air supply to the pump when it is running without liquid.

The Verderair HC-PURE series of hygienic two-membrane pumps is designed for various processes in the food, pharmaceutical and cosmetic industries. The highest hygiene principles are observed in the design process. HC-PURE pumps meet the requirements of EC01935 / 2004 and the FDA. The pumps are made of 316L stainless steel in accordance with the highest hygiene standards.

The central unit is made from a single piece of UHMW polyethylene or PA polyamide and is available in ATEX standard. Electropolishing reduces the average roughness, which makes it harder for products to stick and reduces the risk of bacteria getting trapped and contaminated, and the surface becomes more resistant to corrosion. The housing screws and manifold clamps can be easily removed for complete disassembly and cleaning. The molded EPDM/PTFE membranes have a long service life, and the maintenance-free, 100% self-lubricating air valve reduces maintenance and downtime.

The Verderair HC-PURE dual-diaphragm hygiene pump is available in two versions: FD series for hygienic applications at the beginning of the production process and SB series for hygienic applications at the final stage of the production process.

AIR CONTROL PRO-a set of accessories that help regulate the air supply in pumps and protect against premature failure of the air valve and membranes. The Filter-Regulator with semi-automatic drain keeps the pressure of compressed air supplied to the pump at a constant preset level. The Throttle Valve is used in conjunction with a pressure regulator, and the pump can be adjusted even at low flow rates by using the compressed air volume. The Soft Start Valve ensures a slow start of the pump and increases the service life of the membranes. ON-OFF Valve with manual or electric drive. The Flow Stop Valve automatically cuts off the air supply to the pump when it is running without liquid.

The Verderair HC-PURE series of hygienic two-membrane pumps is designed for various processes in the food, pharmaceutical and cosmetic industries. The highest hygiene principles are observed in the design process. HC-PURE pumps meet the requirements of EC01935 / 2004 and the FDA. The pumps are made of 316L stainless steel in accordance with the highest hygiene standards.

The central unit is made from a single piece of UHMW polyethylene or PA polyamide and is available in ATEX standard. Electropolishing reduces the average roughness, which makes it harder for products to stick and reduces the risk of bacteria getting trapped and contaminated, and the surface becomes more resistant to corrosion. The housing screws and manifold clamps can be easily removed for complete disassembly and cleaning. The molded EPDM/PTFE membranes have a long service life, and the maintenance-free, 100% self-lubricating air valve reduces maintenance and downtime.

The Verderair HC-PURE dual-diaphragm hygiene pump is available in two versions: FD series for hygienic applications at the beginning of the production process and SB series for hygienic applications at the final stage of the production process.

AIR CONTROL PRO-a set of accessories that help regulate the air supply in pumps and protect against premature failure of the air valve and membranes. The Filter-Regulator with semi-automatic drain keeps the pressure of compressed air supplied to the pump at a constant preset level. The Throttle Valve is used in conjunction with a pressure regulator, and the pump can be adjusted even at low flow rates by using the compressed air volume. The Soft Start Valve ensures a slow start of the pump and increases the service life of the membranes. ON-OFF Valve with manual or electric drive. The Flow Stop Valve automatically cuts off the air supply to the pump when it is running without liquid.

The Verderair HC-PURE series of hygienic two-membrane pumps is designed for various processes in the food, pharmaceutical and cosmetic industries. The highest hygiene principles are observed in the design process. HC-PURE pumps meet the requirements of EC01935 / 2004 and the FDA. The pumps are made of 316L stainless steel in accordance with the highest hygiene standards.

The central unit is made from a single piece of UHMW polyethylene or PA polyamide and is available in ATEX standard. Electropolishing reduces the average roughness, which makes it harder for products to stick and reduces the risk of bacteria getting trapped and contaminated, and the surface becomes more resistant to corrosion. The housing screws and manifold clamps can be easily removed for complete disassembly and cleaning. The molded EPDM/PTFE membranes have a long service life, and the maintenance-free, 100% self-lubricating air valve reduces maintenance and downtime.

The Verderair HC-PURE dual-diaphragm hygiene pump is available in two versions: FD series for hygienic applications at the beginning of the production process and SB series for hygienic applications at the final stage of the production process.

AIR CONTROL PRO-a set of accessories that help regulate the air supply in pumps and protect against premature failure of the air valve and membranes. The Filter-Regulator with semi-automatic drain keeps the pressure of compressed air supplied to the pump at a constant preset level. The Throttle Valve is used in conjunction with a pressure regulator, and the pump can be adjusted even at low flow rates by using the compressed air volume. The Soft Start Valve ensures a slow start of the pump and increases the service life of the membranes. ON-OFF Valve with manual or electric drive. The Flow Stop Valve automatically cuts off the air supply to the pump when it is running without liquid.